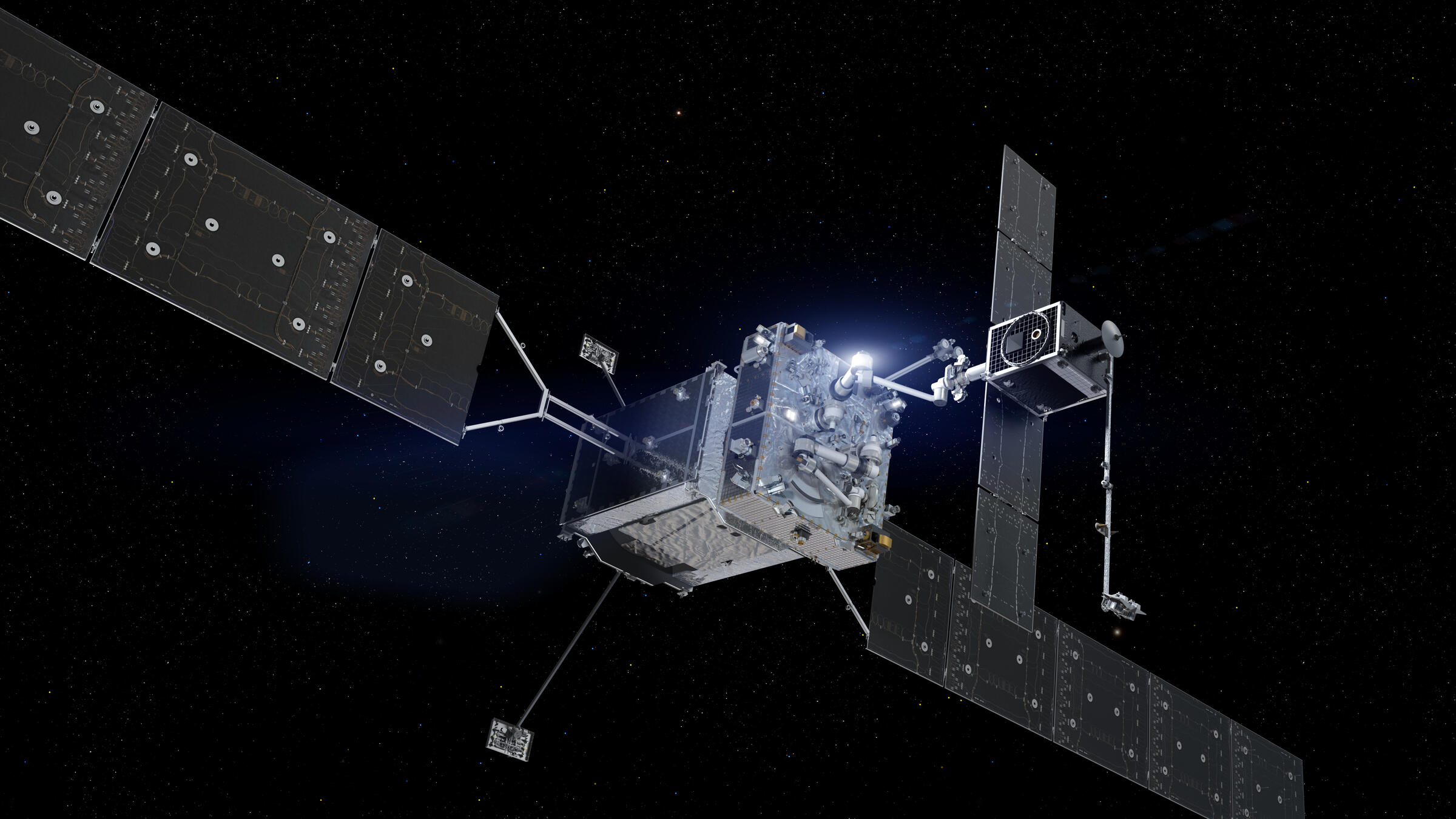

SpaceLogistic’s Mission Robotic Vehicle (left) will grab a client satellite and attach the company’s Mission Extension Pod (right) to provide propulsion to prolong the satellite’s on-orbit life. (Northrop Grumman SpaceLogistics)

WASHINGTON — With recently completed ground-testing and a new commercial client, the public-private partnership between the Pentagon’s far-future research agency and Northrop Grumman’s SpaceLogistics to develop a robotic vehicle to physically repair ailing satellites is moving toward launch in early 2025, according to officials involved.

“There’s a lot of folks who say robotics have been around for a long time. The challenge is space-based robotics,” Robert Hauge, Space Logistics’ president, told Breaking Defense. “This is really, really hard.”

Under the Robotic Servicing of Geosynchronous Satellites (RSGS) program, the Defense Advanced Research Projects Agency (DARPA) is funding the US Naval Research Laboratory to develop the robotic payload, which includes two next-generation robotic arms, multiple robotic tools, cameras for navigation and accompanying software.

The lab has wrapped up three critical developmental milestones as of last month, program manager Bill Vincent told Breaking Defense. “We completed environmental testing… of our second robotic arm system. … We also finished flight qualification testing of our flight software suite that controls and operates the payload. And we finished some performance testing on our robotics testbed.”

Vincent explained that the new, highly dexterous robotic arms are many leaps ahead of the Canadarm used by astronauts on the International Space Station, in that they are designed to operate “autonomously” to do “inspection, orbital adjustment, repair and upgrade” missions on spacecraft “that were not designed to be grappled.” Thus, the system “requires a lot of software and a lot of algorithms” alongside the new hardware.

“All of the avionics and all of the electronics and all of the software and algorithms that are needed to actually execute that mission go well beyond what’s what anybody’s arm does,” he said.

Once all the ground testing is successfully completed, DARPA then will provide that payload for free to SpaceLogistics, which in turn will mate it on their own spacecraft, called the Mission Robotic Vehicle (MRV), developed solely with company funds. Further, SpaceLogistics is paying for the launch on a SpaceX Falcon 9. The MRV will undertake a series of tests on the robotic arm for DARPA under the RSGS mission.

The MRV is being designed to stay on orbit for 10 years, scooting around in space from one repair job to the next, Hauge said.

He added that “the first robotic arm has actually been mechanically installed onto the spacecraft now. So, I mean, it’s real flight hardware.”

The first missions for the MRV, which will begin in 2026, will be installing what the company refers to as “propulsion jet packs” called Mission Extension Pods on commercial satellites. The pods, which carry electronic propulsion engines and will be controlled by the customers who buy them, can provide six years of life extension for a typical 2,000 kilogram satellite in geosynchronous orbit, according to SpaceLogistics.

While the pods are not funded by DARPA under the RSGS mission, their operations will also provide DARPA and the Space Force with a de facto demo of what they can do, Hauge explained, because the “Venn diagram” of capabilities that the company needs to master for commercial customers significantly “overlaps” expressed military needs.

Space Logistics announced today that it has sold the last of the three pods to Virginia-based Intelsat. Intelsat had previously announced in April that it would buy one of the pods for an undisclosed amount, so this is a second one for the company.

Intelsat “historically [has] always been a leader in new areas, and they’re absolutely the leader as a customer. And they’re seeing the value of in space servicing. So, it’s an important partnership that we have with them,” Hauge said.

Intelsat in 2020 was the customer for SpaceLogistic’s first-of-a-kind commercial satellite servicing mission using a predecessor to the current pods, called the Mission Extension Vehicle-1, to extend the life of one of its defunct satellites by providing propulsion. A year later, a second vehicle docked with an active Intelsat bird to extend its life by five years.

Australian satellite operator Optus announced last February that it too would buy one of the new pods.

The pods and the MRV will be launched into low Earth orbit, and then need to use their own propulsion systems to make their way to geosynchronous orbit some 36,000 kilometers above the Earth, Hauge explained.

“The Mission Extension Pods will take on the order of 10 months or so to get to orbit, and the MRV will be more on the order of about a year of orbit raising just because of the mass of that spacecraft,” he said.

“Those three pods will get distributed next to their clients — their commercial clients, the Optus and the two Intelsat satellites, and then we’ll take the MRV and we’ll go install some capabilities that DARPA wants to see, for example, the ability to grasp spacecraft and be able to go install that [pod] onto a client — all those are capabilities that DARPA wants to see.”

But the US government is “interested in other capabilities as well” beyond just life-extension, Hauge stressed, noting that there is a “lot of interest now” in “space mobility and logistics” — a new term of art within the Space Force and US Space Command for allowing spacecraft to maneuver in space, rapidly and often, over a long period of time.

“The US is making a major push to make their newer satellites more resilient. We’re coming along saying, ‘There’s another alternative here, which is we can actually extend and enhance the spacecraft that you’ve got,'” Hauge said.

For example, he noted, SpaceLogistics could swap out the current electronic propulsion systems on the Mission Extension Pods and replace them with chemical propulsion engines, to provide “higher thrust to be able to move a big spacecraft more quickly.” Further, the Mission Extension Pods could be used to strap new capabilities onto an existing satellite. “We could host … a space domain awareness sensor. We could host countermeasures,” Hauge said.

He added that the company’s plan for the future is to be able to upgrade pods already in use by customer satellite.

“Let’s say you had some ‘protect and defend’ capabilities on an existing government satellite. We could come back three, four or five years later, and come up to that satellite, take the old one off and put a new one and now you’ve got the next generation of capabilities,” he said.

Finally, Hauge said that SpaceLogistics is working with the Space Force, and doing self-funded research to develop satellite “interfaces” that would allow direct repairs, rather than simply “strapping on” a pod.

“If a spacecraft in the future actually had a port for power and data, you move out of the realm of a pod that gets launched and spend nine months orbit raising and so forth. I now could take literally a box. I could put the payload inside that box with a solar array and just up a battery to keep it warm. I put that on a ride share. It goes up to [geosynchronous orbit]. It might be there for days, weeks or months. It doesn’t really matter; it depends on the client. The MRV now comes along and grasps this box, brings that box over to that geo[synchronous] spacecraft and plugs it in. We could replace a bus component, we could replace a payload component, we can replace countermeasures,” he said.

“That’s really where we want to take this market with the MRV. And let me be more specific. Because the reason I say box is, I don’t need big solar arrays. I don’t need big batteries. I don’t need star trackers. I don’t need GPS. I don’t need flight computers. I don’t need rendezvous and proximity sensors. I bring all those costs down to just hosting the payload itself. And that’s where we think the real benefit to the government and commercial customers will be out there in the future,” Hauge said.